专注精密测量行业20年!Focus on R&D of precision measurement instruments since 1999,

通过ISO9001:2000国际质量体系认证;ISO9001:2015 qualified

通过高新技术企业认证;High and new technology enterprise qualified

圆度仪国家标准的起草单位;National standard participant of roundness meter

通过出口欧盟CE认证;CE Certificated

产品多样化:可根据客户需要订做;Wide-variety Product, and customizable

(图片样式仅供参考,2022年会发货新款样式)

仪器测量原理Measurement Principle

采用半径测量法,工件旋转式。运用高精度气浮主轴作为基准;采用精密圆光栅、精密电感位移传感器和计算机组成。对被测工件进行计量角度、径向位移量,保证测量工件的角位移、径向值的精确度;测量软件采用基于中文版Windows操作系统平台的DTP系统测量软件,完成数据采集、数据处理及打印输出等工作。

● Radium measurement

● Workpiece rotation

● High precision air floating spindle

● Advanced computer, imported encoder ,accuracy inductive transducer

● Windows based software for data acquisition, process and printing.

测量功能Main Function

圆度、同轴度、同心度、跳动量、垂直度、平行度、平面度、表面波纹度(Wc、Wp、Wv、Wt、Wa、Wq)、频谱分析、波高分析等。

圆度评定方式(4种):zui小区域法、zui小二乘法、zui小外接圆法、zui大内切圆

圆度滤波方式:1、1-500、1-150、1-50、1-15、

波纹度滤波方式:3-16、3-17、15-500、17-100

滤波形式:高斯(ISO标准)

● Roundness of ring shape components.

● Surface Waviness (Wc, Wv, Wt, Wa, Wq) ,

● Power Spectrum Analysis,

● Wave Height Analysis,

● Concentricity ,Coaxiality, Squareness, Parallelism, Flatness etc.

Assessment methods: LSC、MZC、MIC、MCC

Filtering Band: 1-500、1-150、1-50、1-15、3-16、3-17、15-500、17-100

Filter Method: Gaussian (ISO Standard)

技术参数Main Parameters

| 项目 Item | 参数 Parameter | |

| 测量范围 measuring range |

zui大直径 | ф180mm(可扩展) |

| Max. dia. | ||

| zui小内径 | ф5mm | |

| Min. inner dia. | ||

| zui大高度 | 420mm | |

| Max height | ||

| 主轴精度 Spindle accuracy |

径向误差 | ±(0.025+5H/10000)μm |

| Radial error | ||

| 轴向误差 | ±(0.02+6X/10000)μm | |

| Axial error | ||

| 工作台 Workbench |

台面直径Table dia. | φ180mm |

| 回转直径Rotation dia. | φ300mm | |

| 承载重量Load Wt. | 25Kg | |

| 调整范围 | 调偏心±2mm ; 调水平±1° | |

| Adjustment range | Adjust the eccentricity ±2mm; adjust the level ±1° | |

| 旋转速度Rotation Speed | 0-12 rpm | |

| 水平臂 Horizontal arm |

水平移动距离 | 150mm |

| Horizontal moving distance | ||

| 移动速度Moving speed | 0.5-6mm/s 或手动 0.5-6mm/s or manual | |

| 传感器 sensor |

量程range | 500μm (半径差) 500μm (radius difference) |

| 分辨率Resolution | 0.005μm | |

| 测针形状 | φ2mm宝石球测头(有更多直径可选择) | |

| Stylus shape | φ2mmRuby tip (φ1mm、φ0.5mmoptional) | |

| 测力 | 1-12g | |

| Meas. force | ||

| 数据采集 | 进口光栅7200点/周 | |

| Data acquisition | Imported grating7200 points/cycle | |

| 放大倍率 | 任意至zui大20万倍 | |

| Magnification | Arbitrary to maximum 200,000 times | |

| 气源压力Air Source | 0.45~0.80Mpa | |

| 气源流量Air consumption | ≥0.2 m³/min | |

| 电源Power | AC 220V±10% 50Hz | |

| 环境要求Environmental conditions | 温度(T):10~30℃;相对湿度(RH):<85% | |

技术亮点Technical highlights

采用高精密气浮主轴,永不磨损,保持长久精度

High-precision air-floating spindle, never wear, long-term accuracy

数据采集运用进口精密圆光栅、准确度高,稳定性好

Data acquisition by high precision encoder with high accuracy and good stability

部分圆弧亦可测量处理

Part of the arc can also be measured and processed

自动识别轮廓间断,自动或手动剔除功能

Automatic identification of contour discontinuities, with automatic or manual elimination function

软件支持中英文一键切换

Software supports one-click switching between Chinese and English

支持winXP、win7系统

Support winXP, win7 system

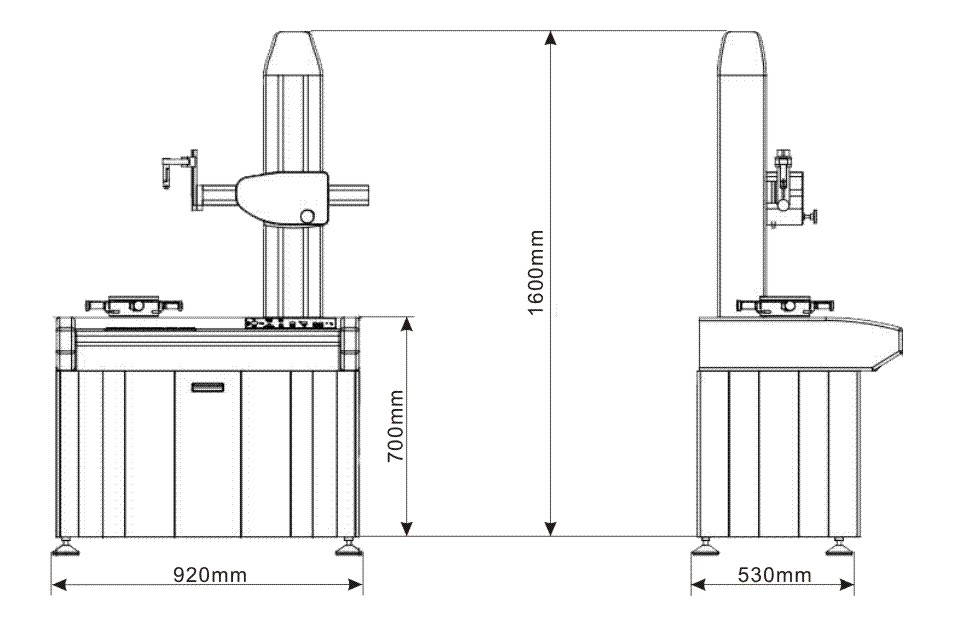

设备尺寸

|

产品(Product) |

包装(Packing) |

总重量 (Wt.kg) |

体积 (CBM m³) |

||||||

|

Lx |

Ly |

Lz |

Wt(kg) |

Lx |

Ly |

Lz |

Wt(kg) |

||

|

920 |

600 |

1600 |

240 |

1000 |

700 |

1700 |

50 |

290 |

1.2 |

使用要求Usage requirement

空压机气源压力:0.45~0.80Mpa Air supply: 0.45~0.80Mpa

空压机气源流量:≥0.2m3/min Air flux: ≥0.2 m³/min

功率需求:约500W;交流220V±10%,50Hz Power supply: AC 220V±10% 50Hz

环境要求:温度:10~30℃;相对湿度:<85%

Environment requirements: Temperature: 10~30℃; RH: <85%

安装地点无明显振源 No obvious vibration

单独地线 Separated grounding wire

主要配置Main configuration

| 部件名称 | 项目名称 | ||

| Part Name | Description | ||

| 机械部分 Mechanical Part |

主机仪器架 Host Stand x1 | ||

| 大理石工作台面 Granite table x1 | |||

| 高精密气浮主轴 High precision air bearing spindle x1 | |||

| 大理石立柱系统Column x1 | |||

| 横导轨移动装置Guide Rail x1 | |||

| 调心调平工作台 Centering & Tilting Adjustable Plate |

台面直径Ф180mm、台面高度50mm | ||

| Table diameter Ф180mm, table height 50mm | |||

| 调整范围:调偏心±2mm ; 调水平±1° | |||

| Adjustment range: Centering ±2mm; Tilting±1° | |||

| 精密三爪卡盘 Precision Chuck |

外尺寸装夹范围:ф1 mm ~~ф81mm | ||

| Outer clamping range: ф1 mm ~~ф81mm | |||

| 内尺寸装夹范围:ф31 mm ~~~ф70 mm | |||

| Inner clamping range: ф31 mm ~~~ф70 mm | |||

| 空气过滤系统 Air Filter System x1 | |||

| 电器部分 Electrical Part |

电器控制系统Electrical control system x1 | ||

| 圆光栅编码器Imported rotary encoder x1 | |||

| 电感传感器Inductive sensor x1 | |||

| 电脑Computer x1 | |||

| HP喷墨打印机HP Inkjet Printer x1 | |||

| 测量软件Software x1 | |||

| 标准件 | 标准玻璃半球Standard hemisphere x1 | ||

| Standard Parts | 椭圆标准件 Elliptical standard x1 | ||

安装、验收

1、安装与培训

1.1我公司负责在用户现场对设备行进安装和调试;

Supplier is responsible for Installation and testing on user site.

1.2在设备安装调试时对买方技术人员进行理论、实际操作及维修等培训,使用户技术人员掌握设备操作,能熟练使用设备进行检定工作,保证设备正常运行并能排除设备的一般故障和特殊保养。.

The user will be trained in theory, operation and maintenance during installation, to that the user could operate the equipment skillful, and could solve the general trouble and make routine maintenance.

2、验收

2.1验收标准:按现行国家检定规程以及合同技术协议为准。

Acceptance criteria: According to the current national verification procedure and the technical agreement of the contract.

2.2验收项目:核对该设备的供货清单,如有漏项和短缺,我司负责免费补齐。

Acceptance items: check the supply list of the equipment. If there are any missing items or shortages, our company will make up for them free of charge.

售后服务

质保期:设备安装验收合格之日起12个月内,但不超过发货之日起15个月。

Warranty period: 12 months from the date of equipment installation and acceptance, but not more than 15 months from the date of shipment.

质保期内:实行“三包”政策,公司负责为用户免费提供计量测试技术咨询服务。

Warranty period: Three guarantees, meanwhile providing free testing or technology consulting

质保期外:我公司提供终身优惠服务和技术支持,设备出现故障需要修理时,所换零件按成本价收取。我司有备品备件库,终身负责为用户以成本价提供备品备件服务。

After warranty: Providing service and support for life, and spare part with the best price, and if hardware support, the software updating free of charge.

服务响应时间:接到故障请求电话后,5小时内回应,我司通过电话、微信或邮件的方式指导买方排除故障;若故障仍不能排除,将在72小时内派技术人员上门解决问题。

Service response time: within 5 hours upon receipt of the fault request call, our company will guide the buyer to troubleshoot the fault by phone, WeChat or email. If the fault cannot be removed, technicians will be sent to solve the problem within 72 hours.